PET material into the home world, what is the prospect?

This year's major home furnishing exhibitions, building materials exhibitions have coincidentally appeared a new surface material products - PET flat film, not only "parachute" in the major exhibitions, and even in the booth to occupy the C position, PET flat film in the end what is the origin?

First, familiar PET gorgeous transformation

In fact, we are no strangers to PET, PET plastic, PET film are common materials in life. Academically speaking, PET is a polyethylene terephthalate plastic. Due to the highly symmetrical molecular structure, PET material has many excellent properties, optical properties, film forming, weather resistance, etc. are very good, in many areas widely used.

PET flat film is made of PET material for flat film, the use of the process does not evaporate toxic and harmful gases, is a safe and environmentally friendly new decorative materials.

Due to the outstanding electrical insulation properties, PET material has become the favorite in the field of electronic and electrical appliances, which is currently the most widely used PET material in the field, the consumption of the more accounted for 26% of the total consumption; due to wear-resistant and stable, PET in the automotive field also occupies a place; lightweight and high-strength attributes and the requirements of the bottles coincide with the requirements of the bottle, a variety of packaging bottles can be used in the production of PET material!

Now, PET materials come through the air, straight down to the field of furniture, can not play its own advantages to the extreme, in the field of home building materials also make a difference?

Second, the advantages of PET sheet PET film can "break through the wall" into the furniture market, there must be its reasonable value, PET film has a safe and environmentally friendly, rich in style, cost-effective features.

1, safe and environmentally friendly plastic.

Speaking of plastic, there may be people who are worried that plastic will produce toxic substances, such a concern is not unreasonable, in the past, plastic is mostly PVC material, and PVC contains chlorine elements, the production process is not fully polymerized vinyl chloride may overflow, harm to the human body, while PET is the same as acrylic, the material itself is composed of only C, H, O three elements.

PET and PVC from the appearance of a high degree of similarity, but as long as the two will be ignited can be quickly distinguished: PVC because it contains chlorine elements, combustion will produce an irritating odor, while PET combustion will not release toxic gases, is a safe and environmentally friendly plastic.

2, harmonious and versatile colors

PET flat film bright colors, small color difference, not easy to fade, whether used alone, or with other materials, can create a harmonious and unified home environment.

Whether it is refreshing and elegant pure white tones, or low-key noble pure black tones, can be used as the main color of interior decoration, PET flat film in these two tones have to call out the expression.

Pure and simple natural log style has been in the home market has a certain share, PET flat film decorative panels and the fusion of logs, easing the release of the mountains and forests secluded guest sense of comfort.

Rock plate stone is a hot home building materials in the market in recent years, tough and noble performance is its attraction to high-level consumers where the charm of the PET film cold wind color can be naturally integrated into it, but also to offset some of the cold and hard.

3, the form of a variety of models

Matte PET sheet is often called skin feel film, anti-fingerprint film, touch as soft as baby skin, very suitable for use in the closet. Glossy PET sheet surface clean, give a person a bright and gorgeous feeling, the reflection of light can make the whole home environment refreshingly bright.

In addition to the common matte models and glossy models, there are bold and innovative studio to use PET felt material to create furniture, they will be renewable polyester material screening process, made of PET felt material, this material is not only soft and durable, but also has excellent acoustic properties. PET felt material embodies the concept of environmental protection and sustainability, and has become the studio's signature material.

4. Cost-effective new material

Cracking is the most common problem when processing wood-based panels, and PET flat laminating film due to its own material structure characteristics, processing does not blow up, sealing never crack, stable performance, wear-resistant and scratch-resistant, loved by manufacturers.

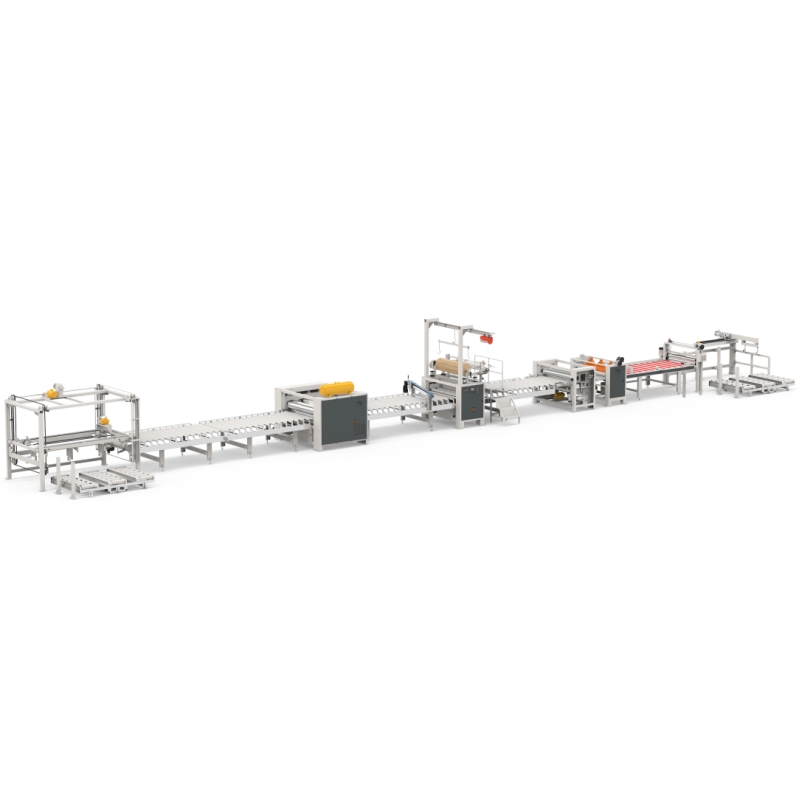

In addition, the price of PET film is relatively cheap, mainly because the cost of the material itself is controllable, and the production method is increasingly towards industry 4.0.

Most of the PET thickness in the market between 0.3 mm ~ 0.6 mm, the thickness of the thinner coupled with the relatively affordable price of raw materials, so that PET flat film is not expensive. At the same time, thanks to its thin thickness, the general PET for the roll material, this advantage makes its pressure paste efficiency greatly improved.

Third, the application of PET film

PET flat film on the market, the earliest can be traced back to a few years ago, probably because the technology is not mature enough, or because the market understands too few people, before has not turned out much of a wave. After several years of dedicated research and publicity and promotion, PET flat laminating film finally came out in 2019, unveiled the mystery and came into the public's view.

At present, PET flat laminating film is commonly used in bathroom, cabinet, closet, decoration veneer and other panel furniture materials.PET flat laminating film is easy to decontaminate, the film surface does not produce static electricity and not easy to adhere to dust in the wiping process. Anti-scratch, wear-resistant, membrane surface is not easy to leave traces, even if often wipe, the surface color is not easy to change, fade. And PET film is easy to mold, with PET film processing molded door panels good sense of three-dimensional.

PET flat laminating film's rapid popularity is not traceable, its style of plasticity is boldly open the door to the market tool.

Throughout the customized home furnishing style in recent years, widely sought after is just that three or four, whether it is from the previous two years has been hot so far the Nordic minimalist style, or in recent years the strong rise of the new Chinese style, or a time of the wind of the light luxury wind, PET flat film can be easily integrated into the scene, and each other's achievements.

Now PET flat film only in the home building materials market came into its own, the future of consumer acceptance, user feedback, whether the performance can be further refined, we wait and see!